Quick Summary (for Importers and Project Managers)

If you source Calacatta slabs in bulk, success depends on system—not luck. This guide reveals how FORUSTONE integrates OEM production, quality control, and ISPM-15 export packaging to guarantee every shipment meets performance and visual standards.

De quarry selection à on-site installation, each phase follows an engineered workflow proven across hospitality, retail, and residential projects worldwide.

What Makes Calacatta Marble So Unique

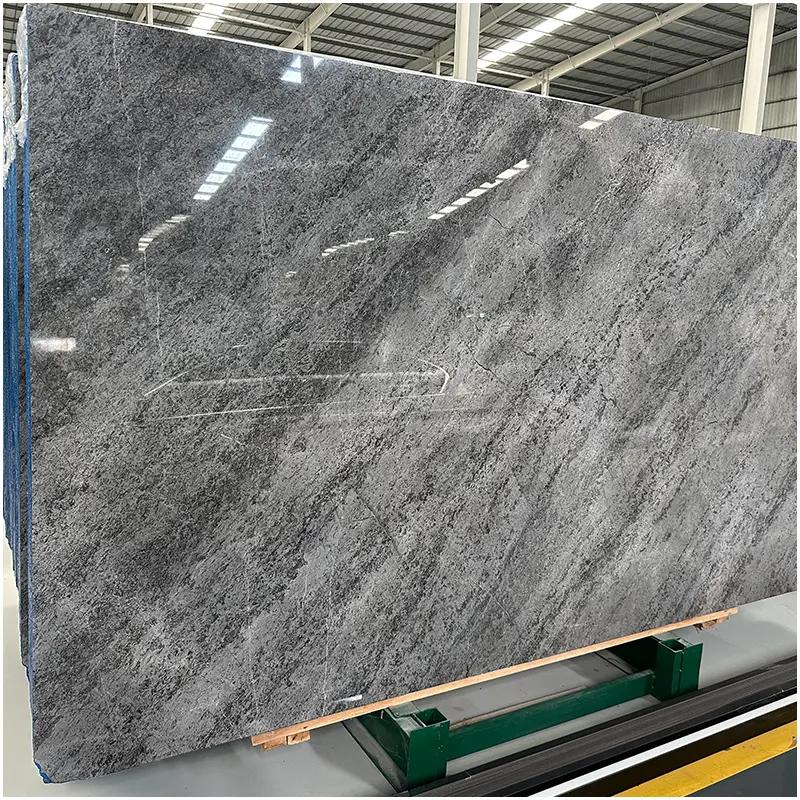

Material Composition and Visual Traits

-

Distinct white background with dramatic grey or gold veining.

-

High calcite purity (>98%) gives translucence and natural glow.

-

Polishes exceptionally well for mirror-like surfaces.

Why Architects and Designers Choose Calacatta

-

Symbol of luxury and timeless European craftsmanship.

-

Ideal for murs caractéristiques, bathroom vanitieset statement countertops.

-

Performs better than softer Carrara marbles under commercial use.

From Quarry to Project — The Journey of Calacatta Slabs

Step 1 — Quarry & Block Selection

FORUSTONE engineers visit the quarry for in-person block approval. Vein orientation, tonality, and structural integrity are verified before cutting.

Key Parameters:

-

Vein pattern uniformity

-

Moisture content and fissure control

Step 2 — Slab Cutting and Calibration

Diamond gang saws slice blocks into uniform slabs (18–30 mm). Calibration ensures consistent thickness and surface tension.

Step 3 — Resin Reinforcement & Polishing

Vacuum resin technology seals micro-cracks; slabs are polished, honed, or leathered.

Step 4 — The Three QC Gates (CR / MA / MI)

-

Pre-cut inspection (CR): color and vein validation.

-

Mid-production audit (MA): edge, warp, and gloss level checks.

-

Pre-shipment inspection (MI): AQL 2.5–4.0 sampling, moisture tests, and crate sealing.

Step 5 — Packing and Container Loading

Each slab is assigned a QR code linking to its production record, photos, and crate number.

Détails de l'emballage :

-

ISPM-15 kiln-dried wood crates

-

Foam cushions + desiccant bars

-

Tilt/shock indicators for long-distance stability

Design Applications and Architectural Brilliance

Residential Design

-

Kitchen countertops with book-matched veining

-

Bathroom walls, flooring, and staircases

Commercial and Hospitality Spaces

-

Hotel lobbies, feature walls, and spa interiors

-

Large-format floor panels with low joint visibility

Exterior and Public Projects

-

Polished façades (ventilated cladding systems)

-

Outdoor paving with anti-slip micro-texture

OEM Fabrication & Customization by FORUSTONE

Comptoirs et plans vasques

Pre-cut sink/faucet holes, finished edges, and matching backsplashes.

Wall Panels & Stair Treads

CNC precision cutting for consistent risers, skirtings, and nosing.

Labeling and Traceability System

QR-coded crate labels record batch, inspector ID, and finishing type.

Factory Pre-Sealing and Surface Protection

Honed/leathered slabs receive breathable sealers; SDS and care guides are included.

Export Packaging & Quality Control Process

Crate Engineering

-

Cross-braced kiln-dried crates

-

Reinforced corner protectors

-

Anti-tilt bottom skids

VGM and Label Traceability

Verified gross mass filed before shipment; crate label matches invoice and inspection photo.

Moisture Control and Long-Distance Stability

Desiccant bars regulate humidity; vents maintain breathable crates for sea transport.

Sustainability and Global Demand

Exploitation responsable des carrières

FORUSTONE partners only with quarries practicing water recycling and controlled blasting.

Eco Resin and Waste Minimization

Low-VOC resins and 95% off-cut recycling rate ensure minimal environmental footprint.

Circular Logistics

Returnable crates and local supplier networks reduce CO₂ emissions by up to 22%.

Expert Insights Calacatta’s

Designer Perspective

“Calacatta’s strength lies in its predictability — FORUSTONE’s batch consistency allows precise bookmatching even across phases.”

- Aria Kim, Interior Architect, Seoul

Importer Feedback

“The three-gate QC system saves weeks of dispute time. Everything’s documented and traceable.”

- Marble Distributor, Dubai

Technical Viewpoint

“Moisture control and VGM accuracy reduce container damage rates below 0.2%.”

- Chen Wei, FORUSTONE QC Director

Questions fréquemment posées

Q1: How much overage should I order for bookmatching?

Généralement 7–12% depending on pattern alignment and on-site trimming.

Q2: Do I need factory pre-sealing?

Yes. FORUSTONE applies vapor-permeable sealers ideal for honed and leathered finishes.

Q3: Which Incoterm should first-time importers choose?

Start with FOB for control; shift to CIF/DDP for simplicity as experience grows.

Q4: How do I verify moisture control before shipping?

Request pre-shipment photos with desiccant placement and tilt indicator activation.

Why the FORUSTONE Method Works

Bulk marble supply doesn’t have to be unpredictable. When QC, OEM, and logistics function as one workflow, you get a zero-defect system.

FORUSTONE’s Calacatta line represents repeatable precision — not luck.

Appel à l'action

📦 Ready to plan your shipment?

-

Get a custom crate plan, QC checklist, and export timeline:

🔗 https://forustone.com/contact-us/ -

Explore Calacatta product families and finishes:

🔗 https://forustone.com/natural-marble-slabs/

Références

[1] Natural Stone Institute – Marble Classification and Standards

https://www.naturalstoneinstitute.org/

[2] Architectural Digest – 2025 Calacatta Marble Design Trends

https://www.architecturaldigest.com/

[3] ISO 12572 – Moisture Control in Natural Stone

https://www.iso.org/

[4] USGBC – Sustainable Quarrying Practices

https://www.usgbc.org/

[5] FORUSTONE Factory Quality Control Handbook, Rev.2025

Semantic Close · Calacatta Marble OEM & Export Workflow

- Poste : Calacatta marble remains the benchmark for luxury interiors — connecting architectural vision with reliable OEM production.

- Design Rules: Precise vein mapping, consistent thickness calibration, and bookmatched continuity define every Calacatta slab.

- Operational Levers: Digital block traceability, three-gate QC system, ISPM-15 certified packaging, and export-ready logistics.

- Norme de qualité : Verified AQL inspection reports and moisture-control crates ensure slabs arrive flawless worldwide.

- Metrics: Yield ratio, polish gloss index, dimensional accuracy, impact tolerance, and delivery time variance.

- Roadmap: Quarry selection → Vein mapping → Precision cutting → Quality calibration → Export verification.

- FORUSTONE’s Offer: OEM + ODM marble fabrication, global shipping assistance, and project-specific customization for hotels, villas, and commercial interiors.